Engineering Through Hands-On Experience

I'm a student of the world who thrives on hands-on work.

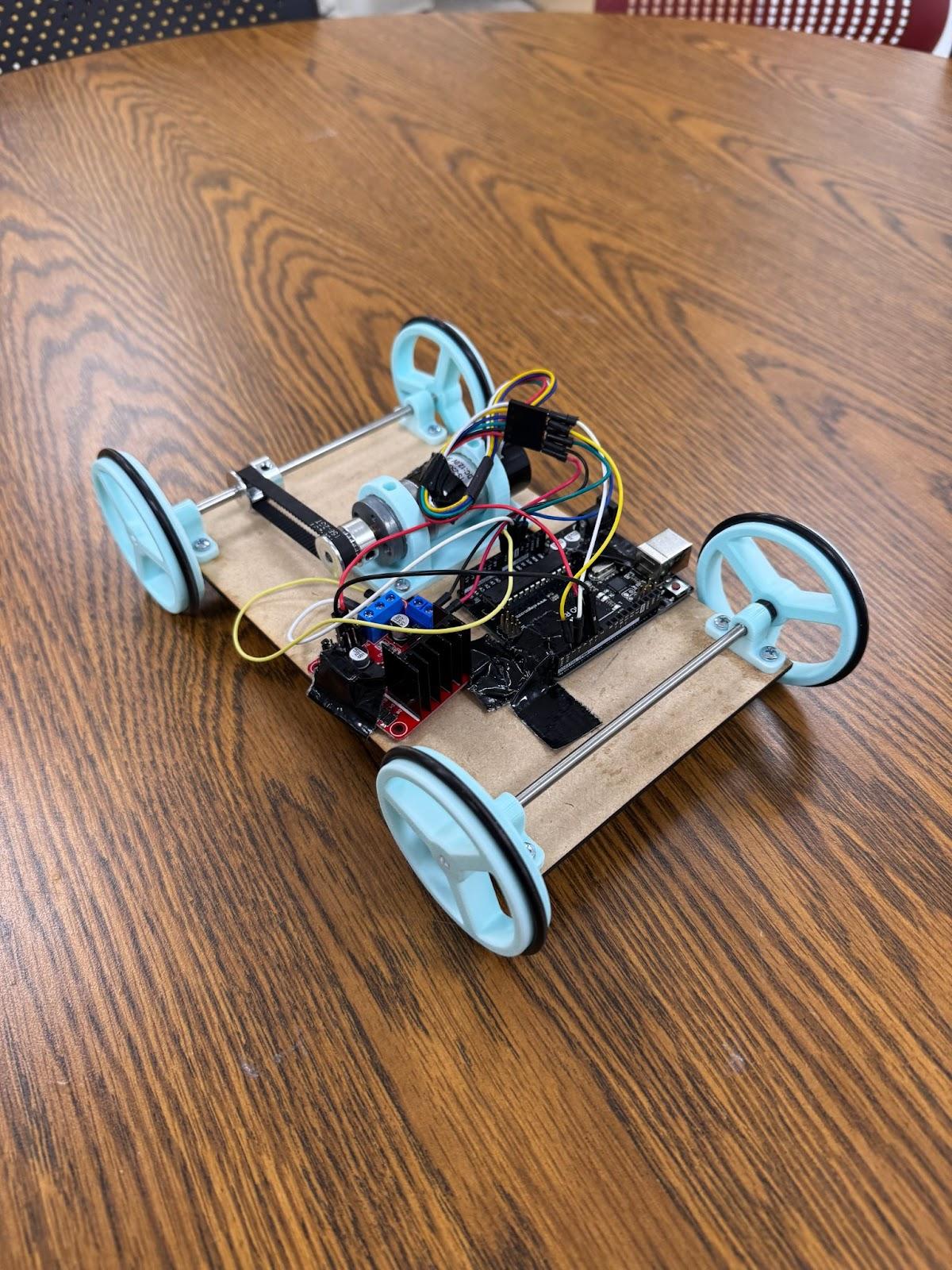

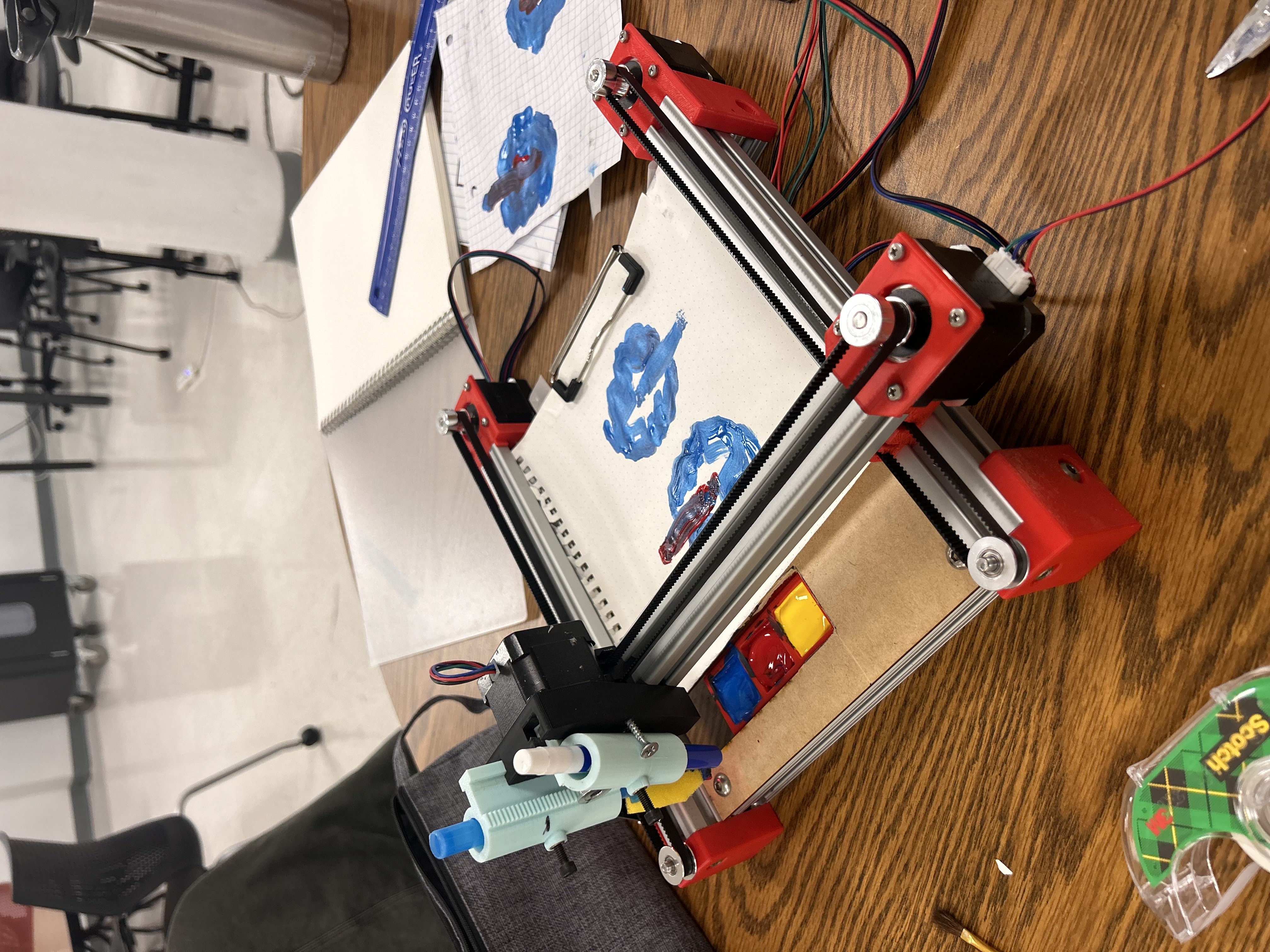

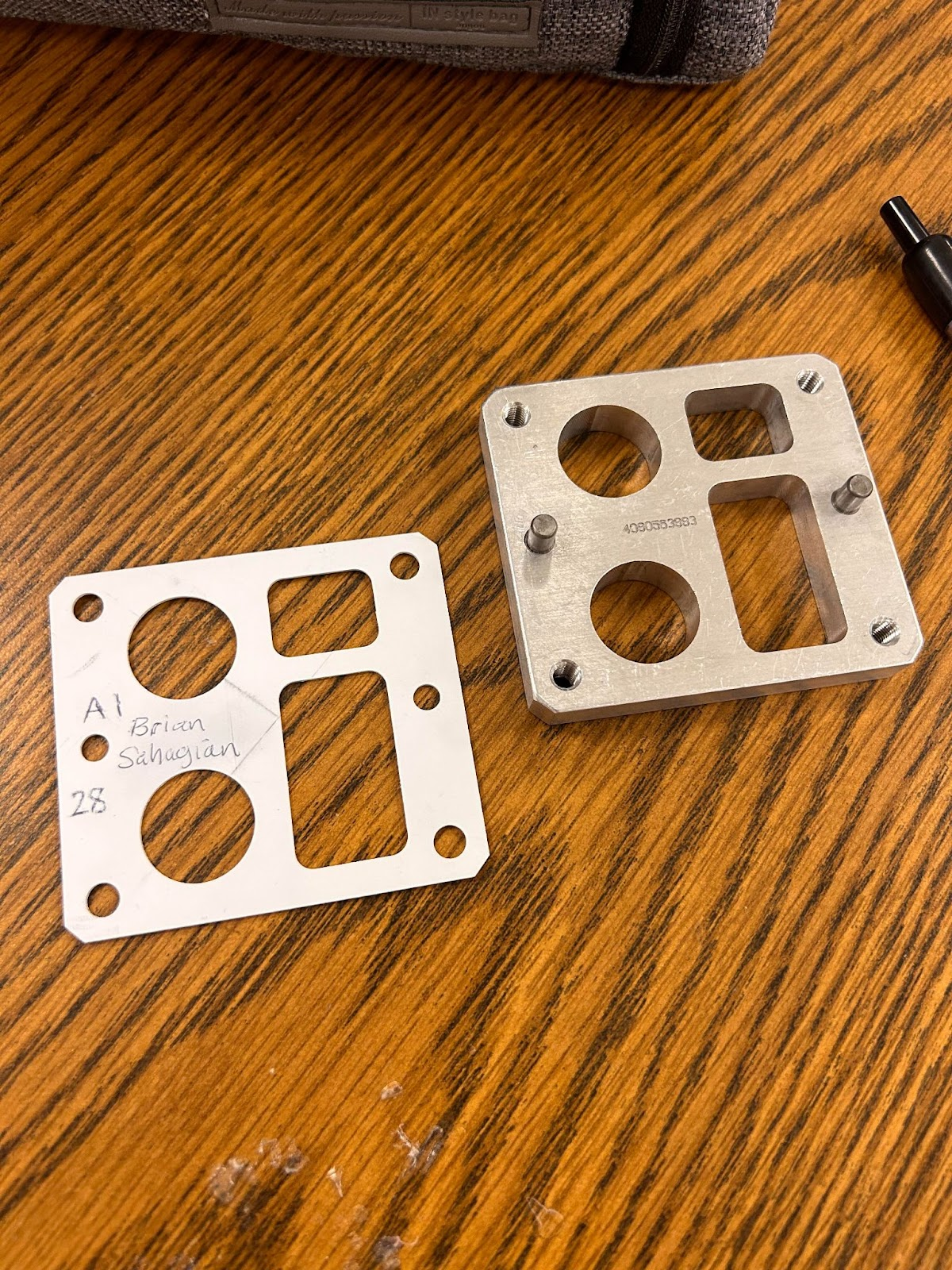

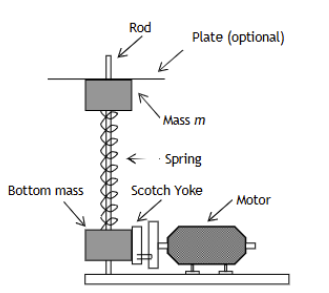

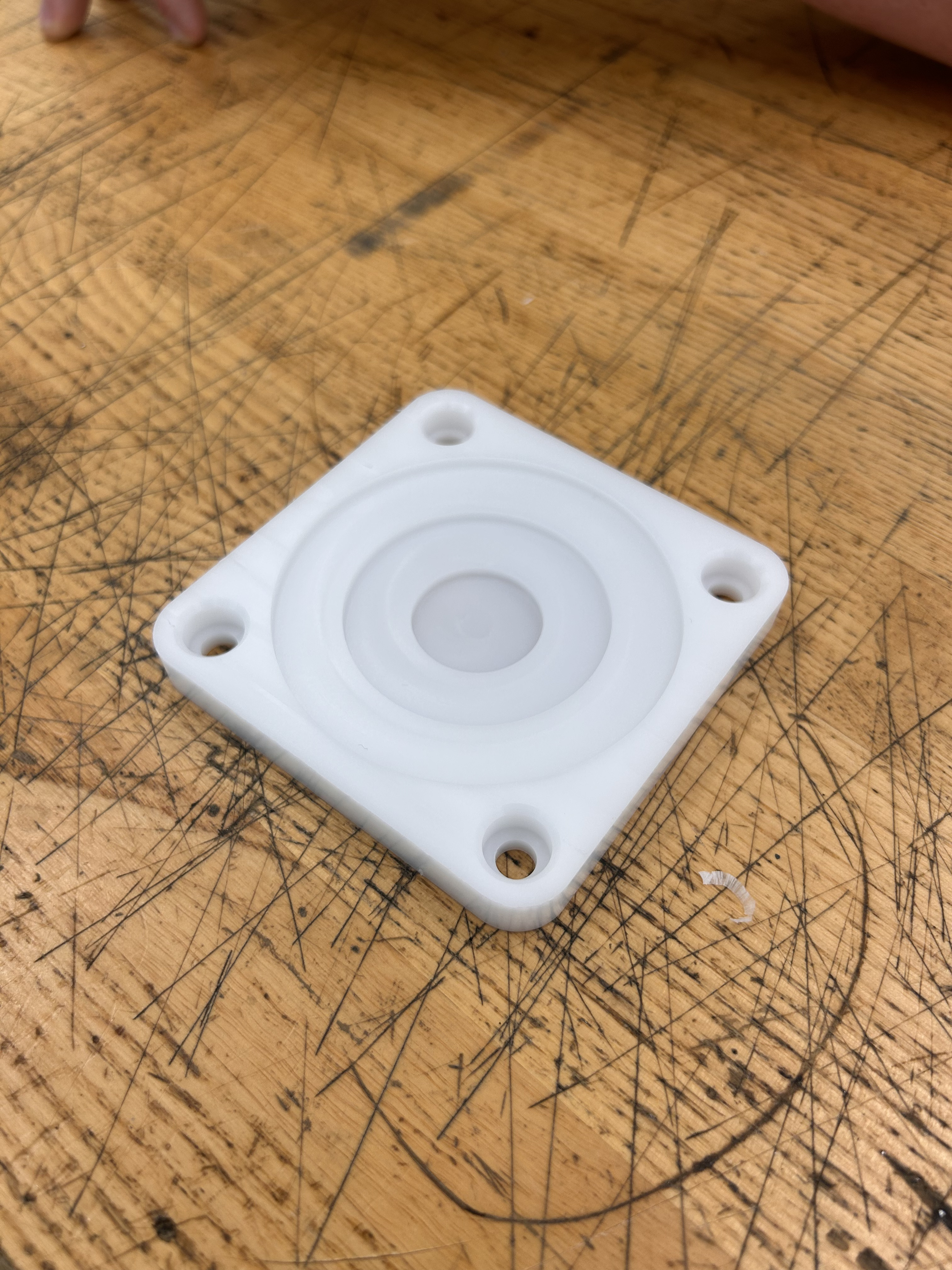

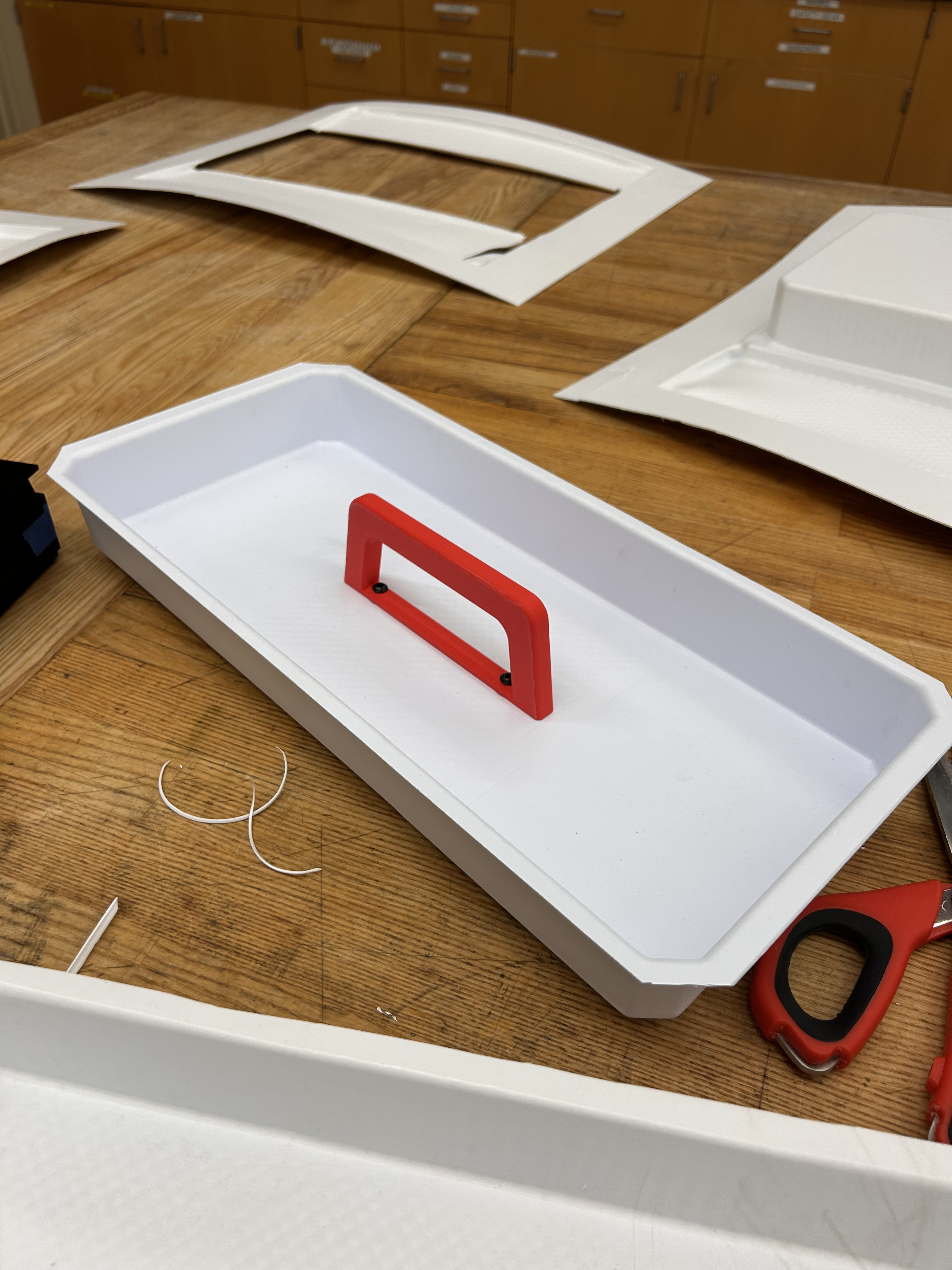

Whether I'm programming Arduino controllers, machining parts in BU's machine shop, or rebuilding 70's motorcycle engines,

I love bringing theoretical concepts to life through practical application. My academic foundation

in mechanical systems and materials science comes together best when I'm actually building something.

My primary interest lies in robotics and software-integrated systems—creating intelligent machines

that can sense and respond to their environment. Outside of engineering, I'm passionate about

photography, skateboarding, snowboarding, surfing, bicycling, and more. These diverse interests keep

me creative and often inspire fresh approaches to engineering challenges.

.JPG)