Complete design and analysis of gasket manufacturing process including material selection, tooling design, and quality control procedures

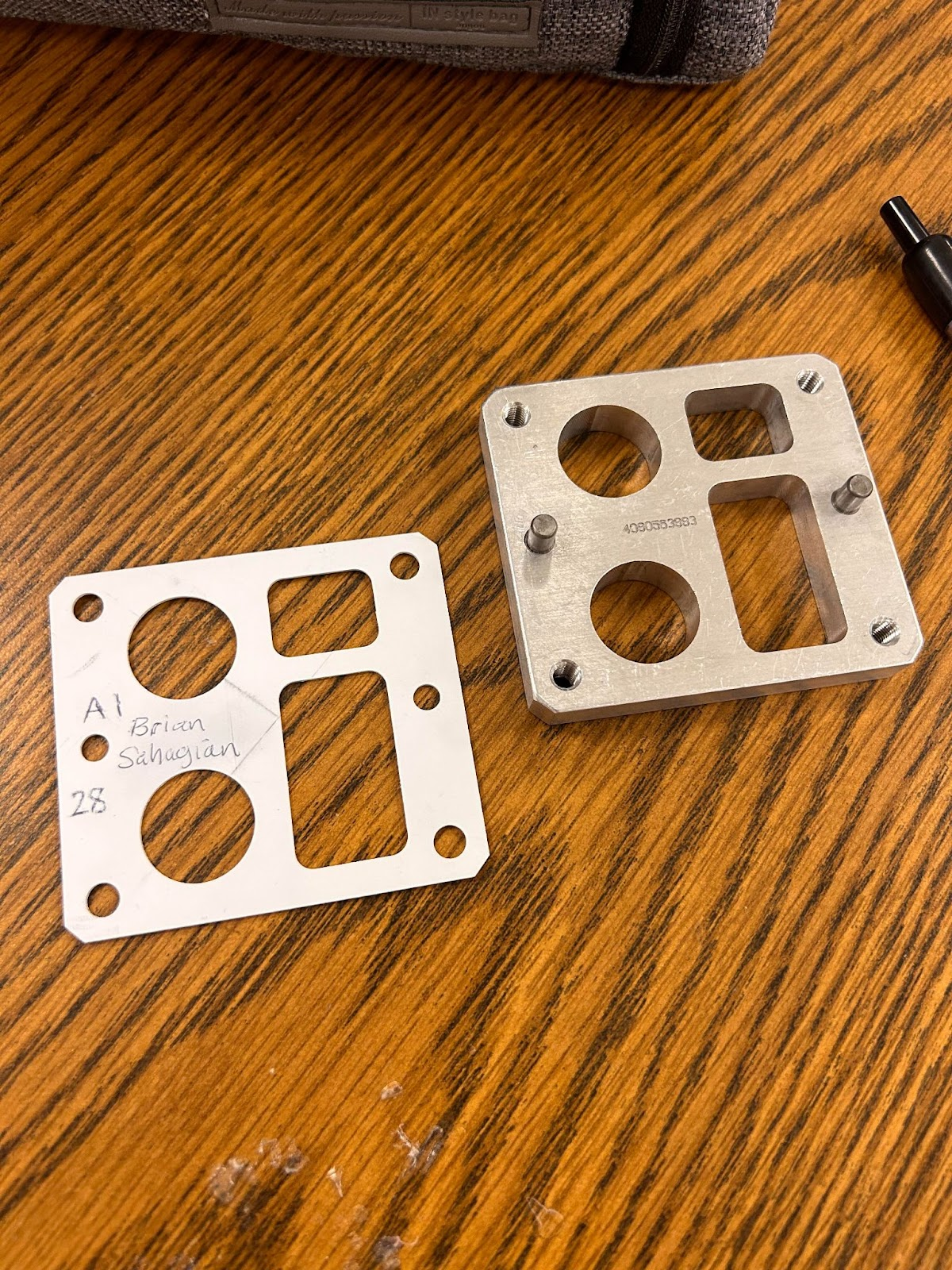

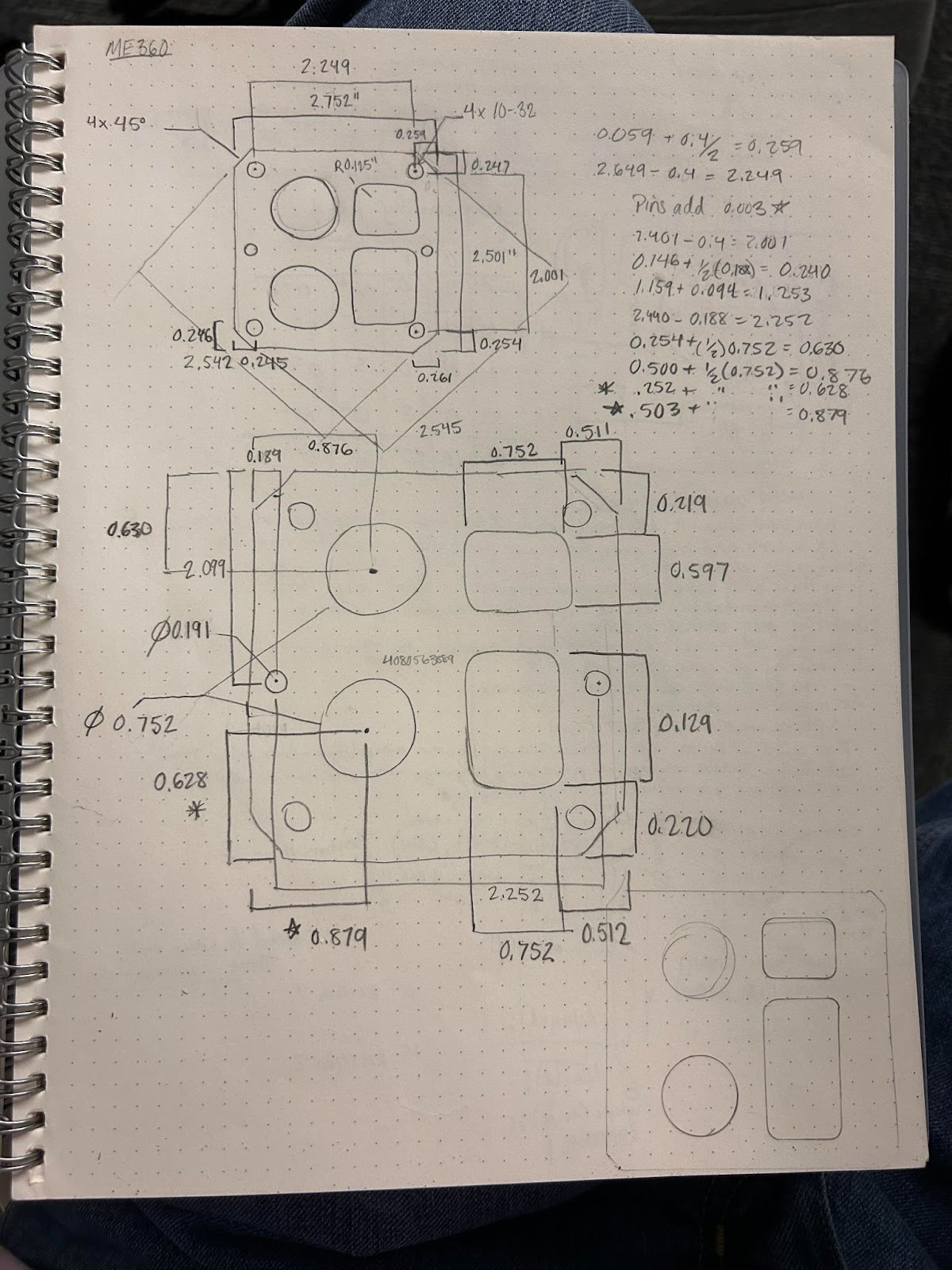

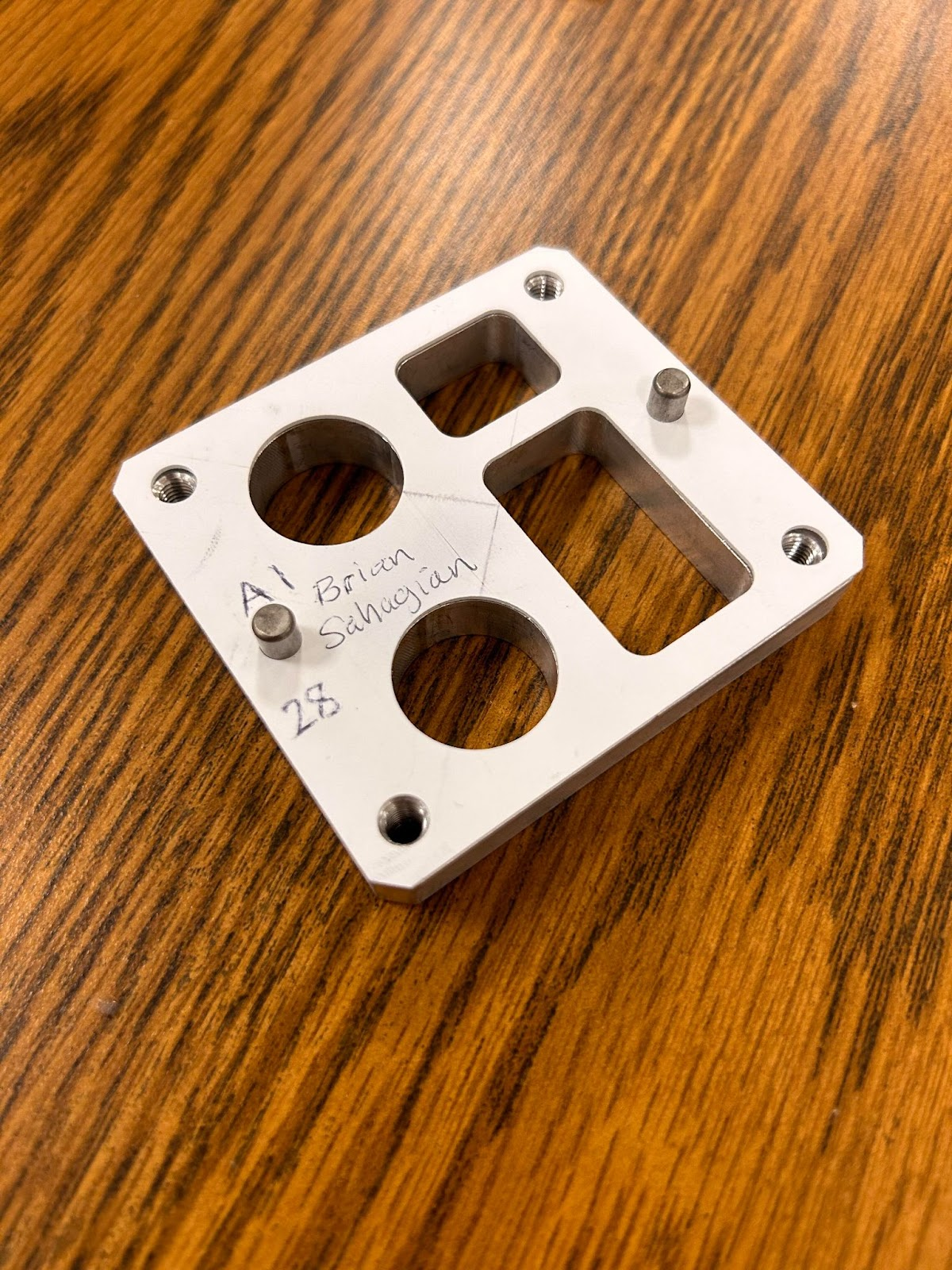

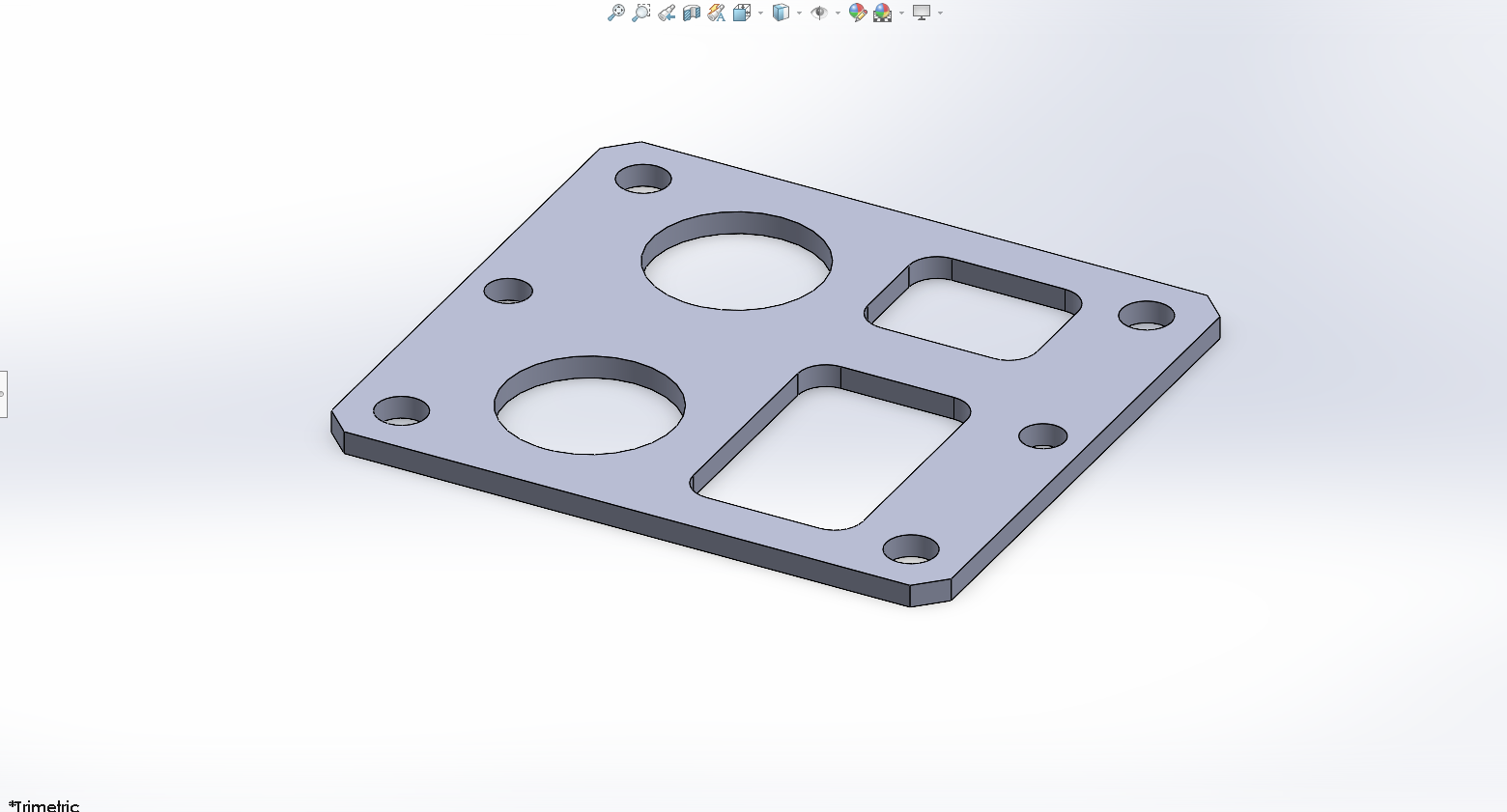

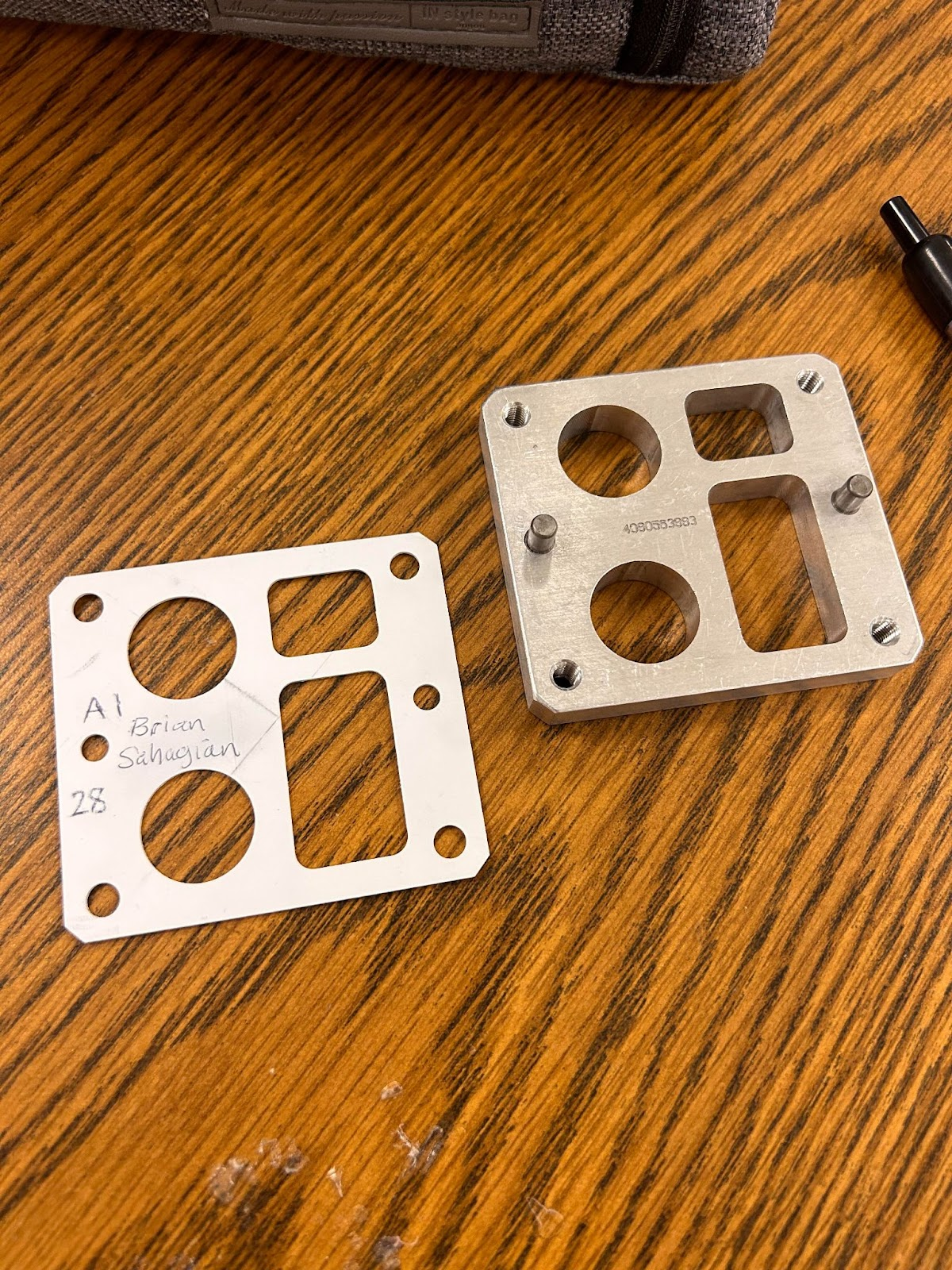

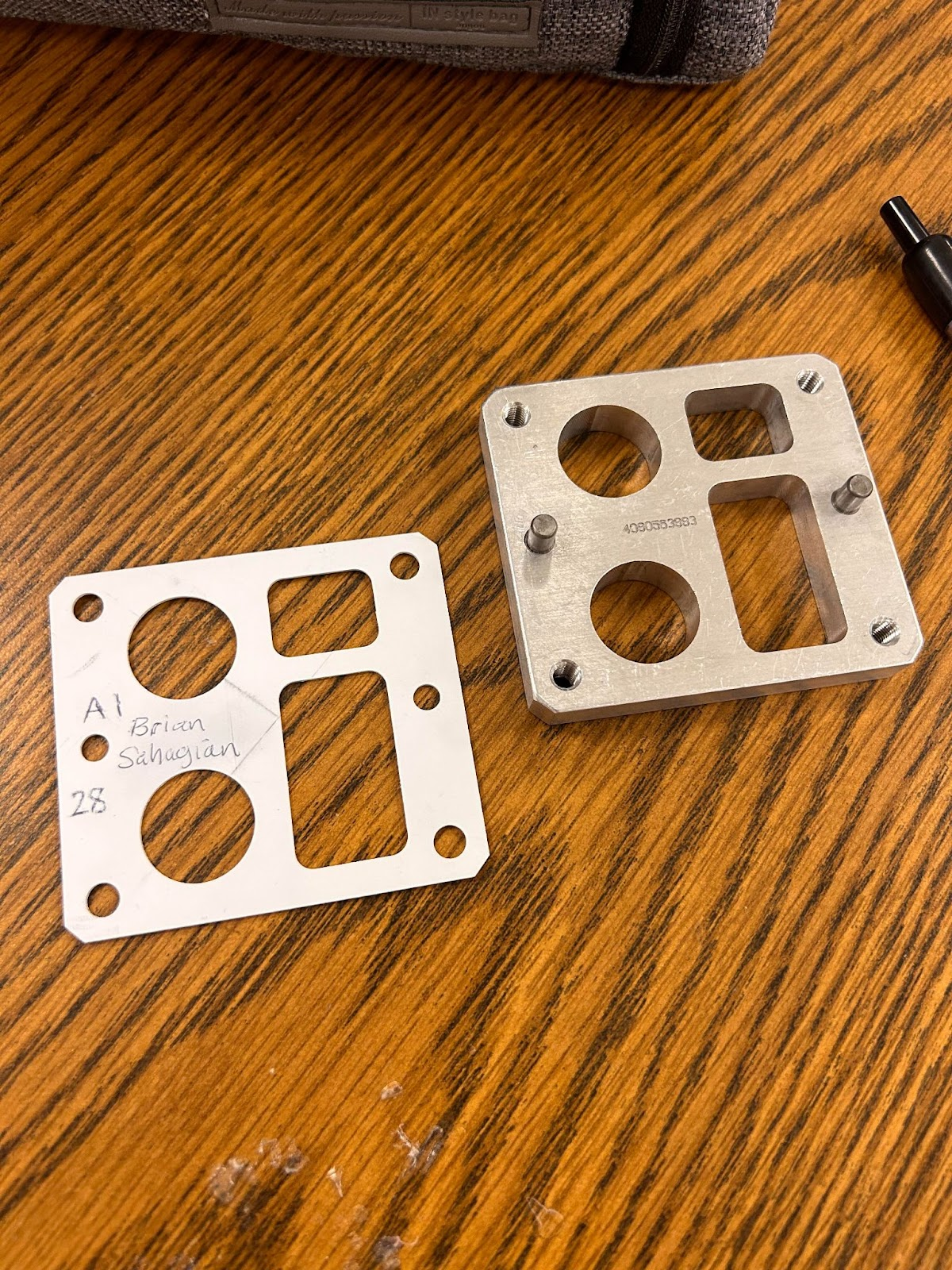

This precision manufacturing project involved designing and producing a custom gasket for a complex aluminum block with multiple holes and extrusions. The process included precise manual measurements, creating technical drawings, 3D CAD modeling in SolidWorks, generating CNC toolpaths with HSMWorks, and machining the final gasket using a HAAS CNC mill at Boston University's manufacturing lab.

Comprehensive documentation of gasket manufacturing process design and analysis