Designed and manufactured custom storage solutions for machine shop organization using vacuum thermoforming and 3D printing integration

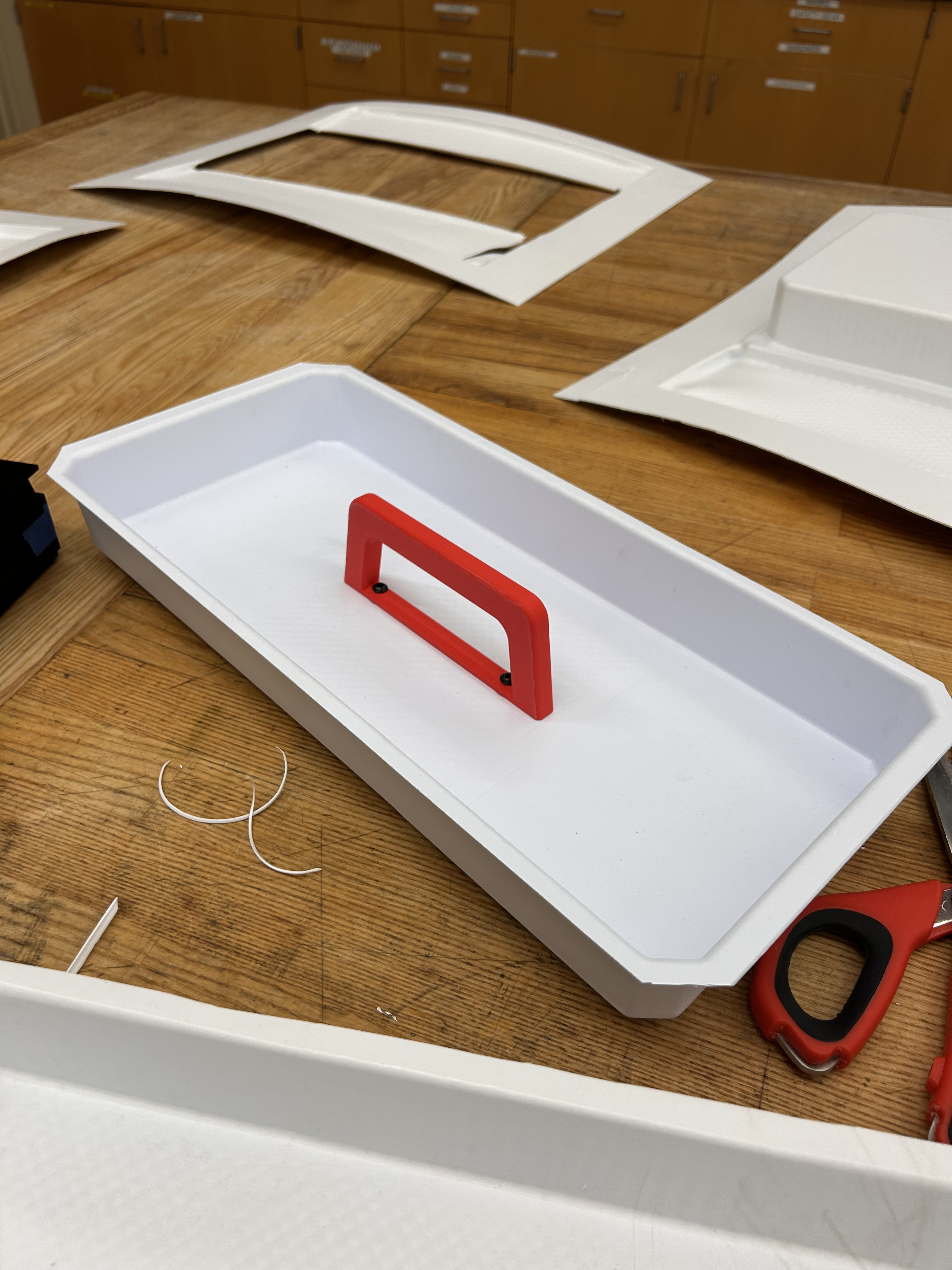

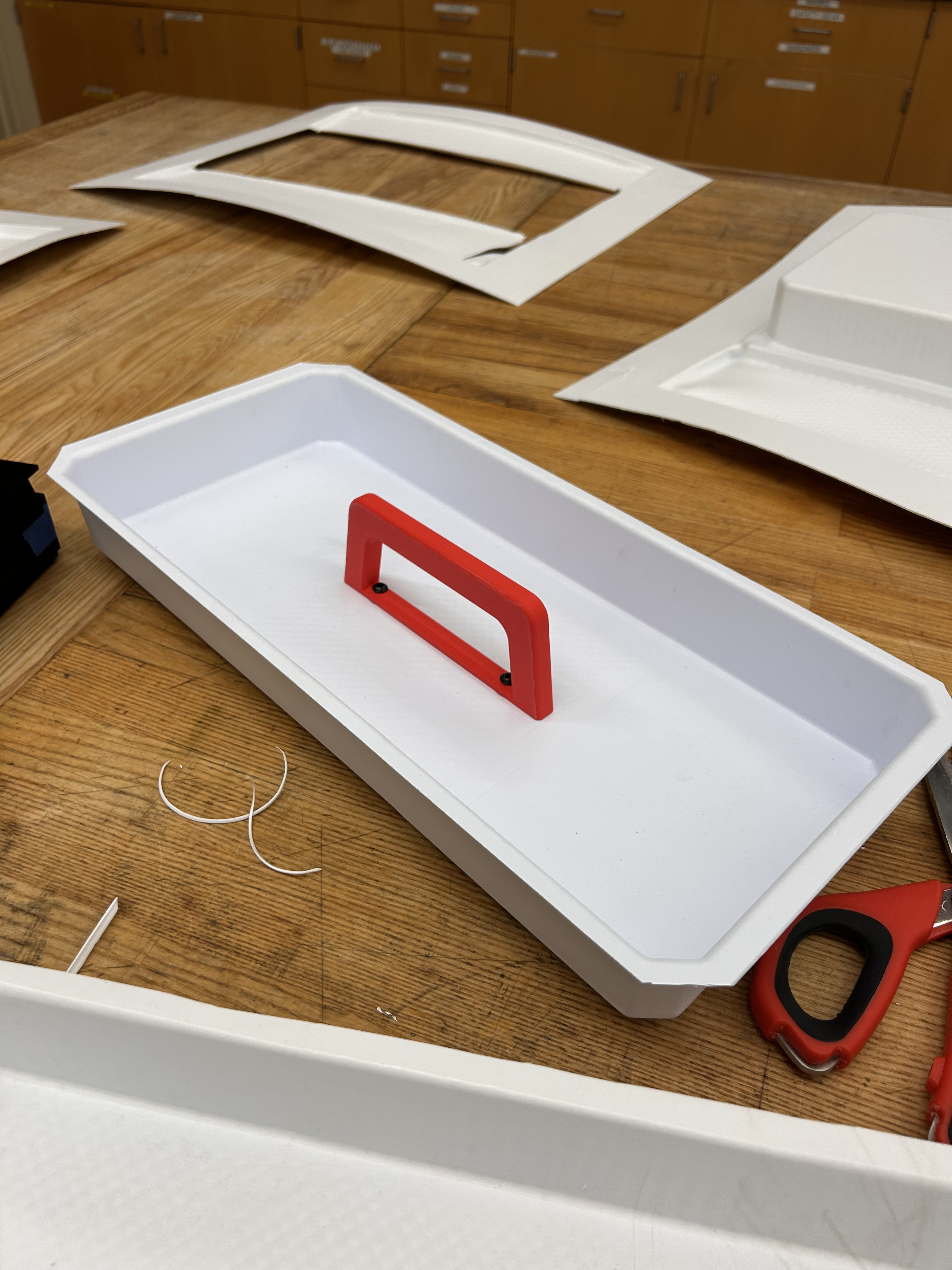

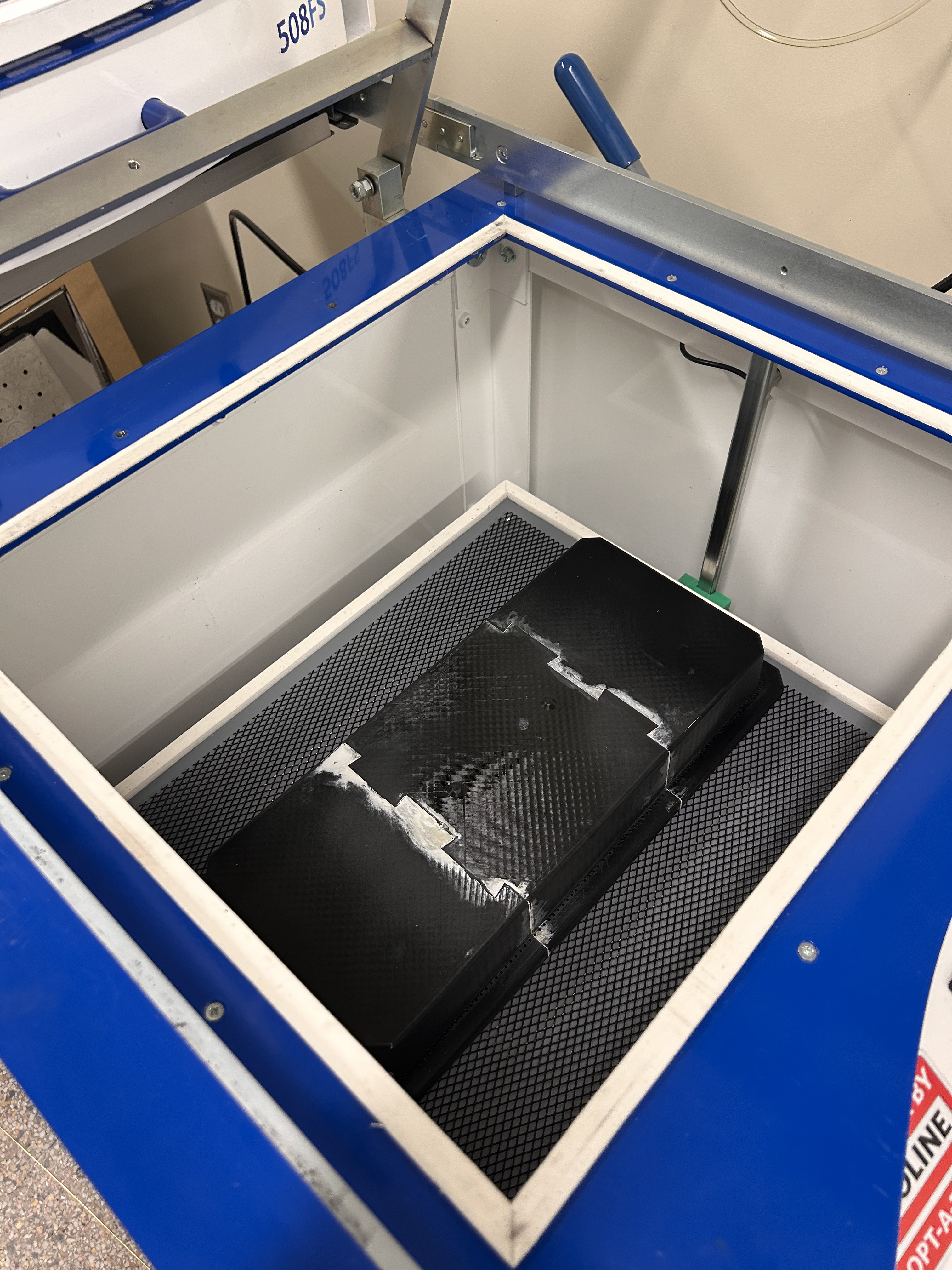

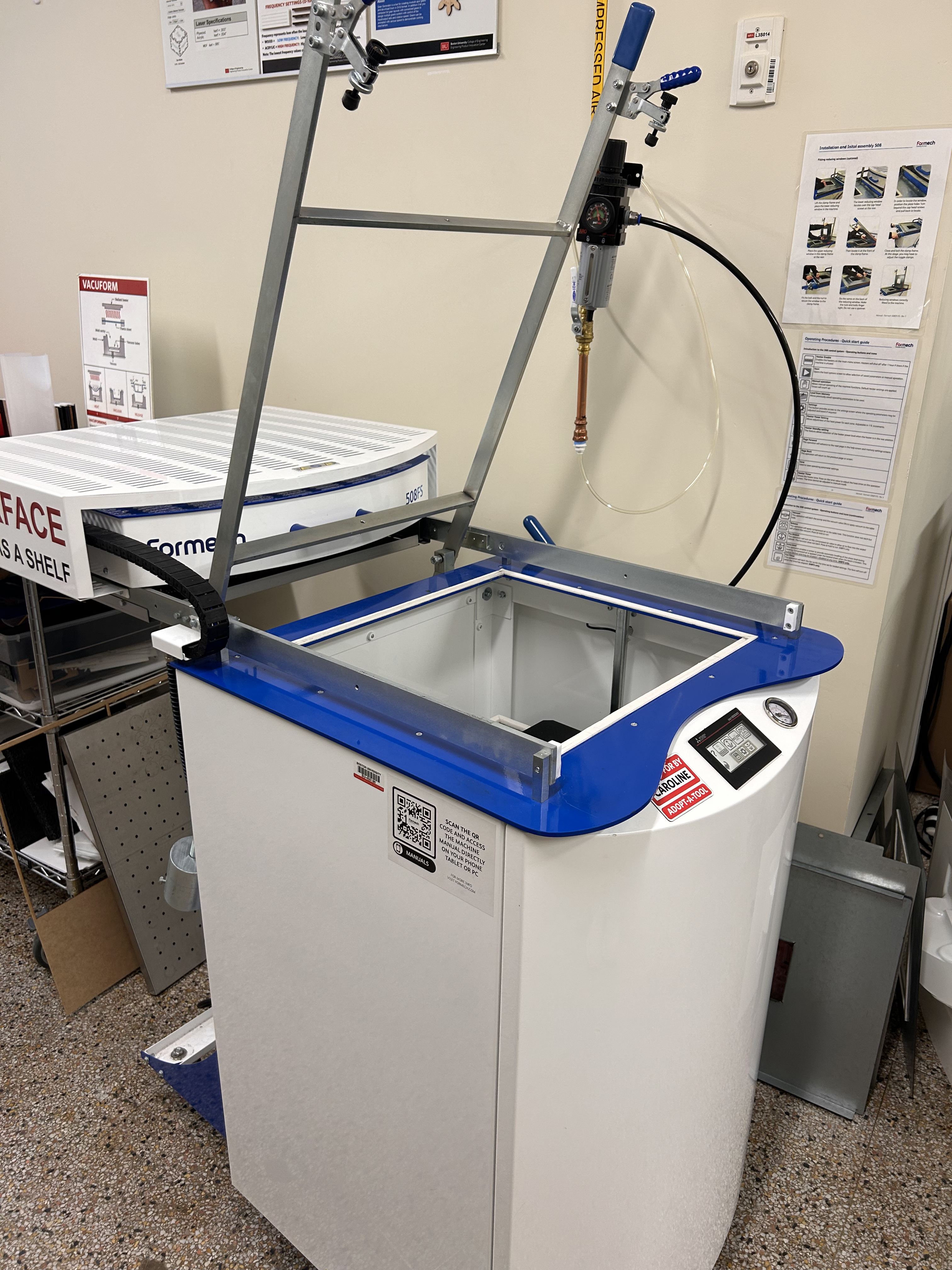

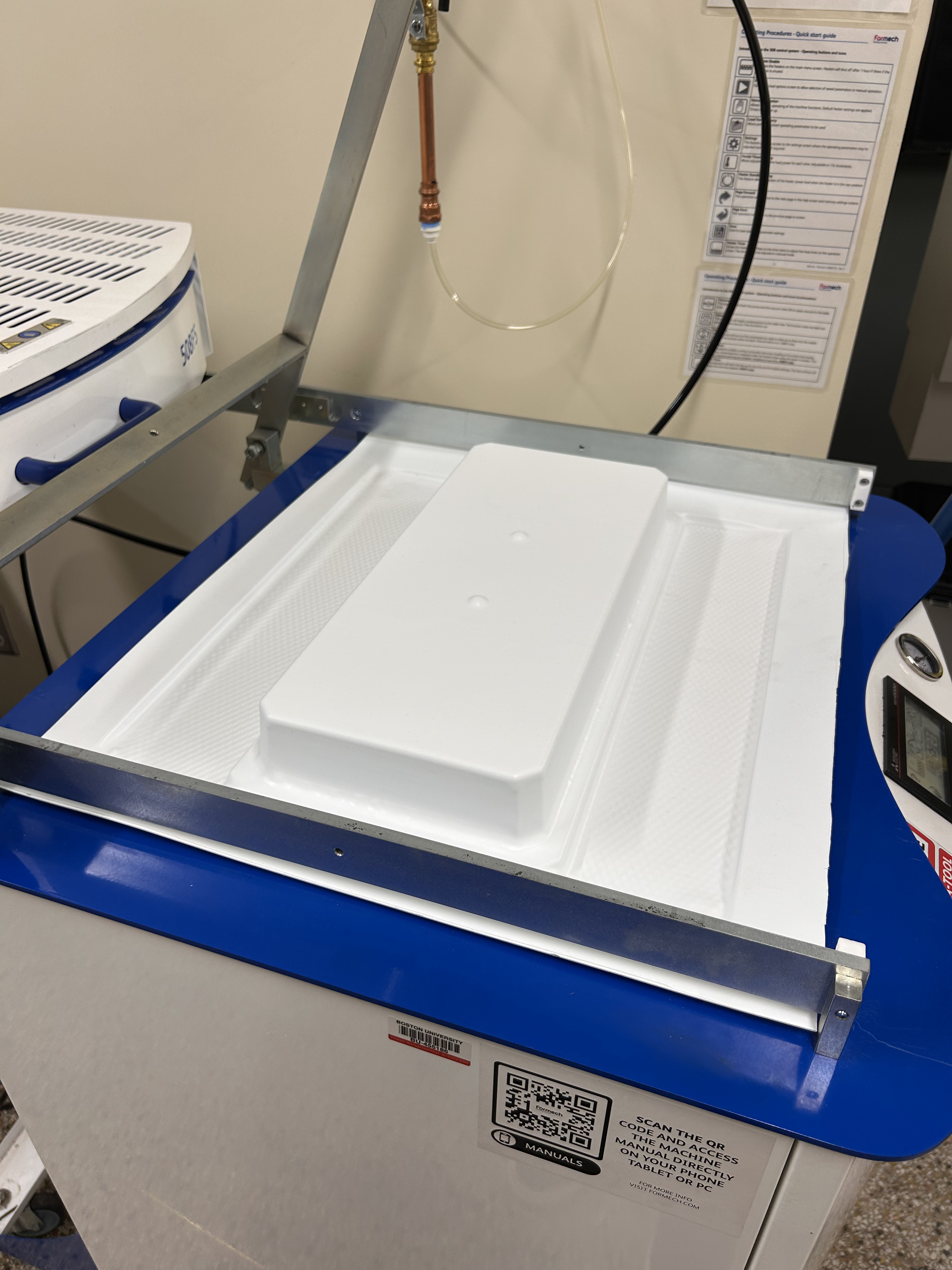

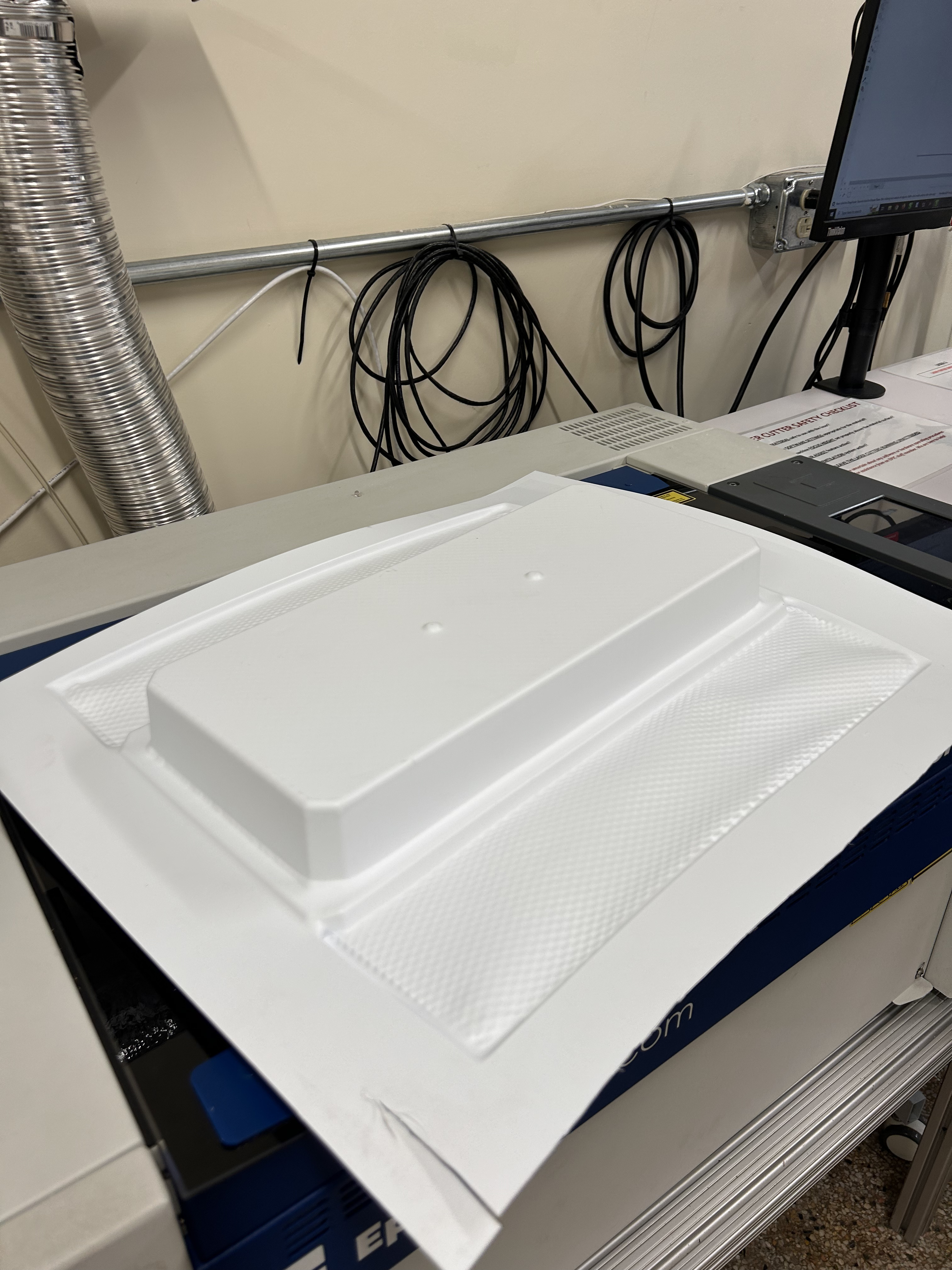

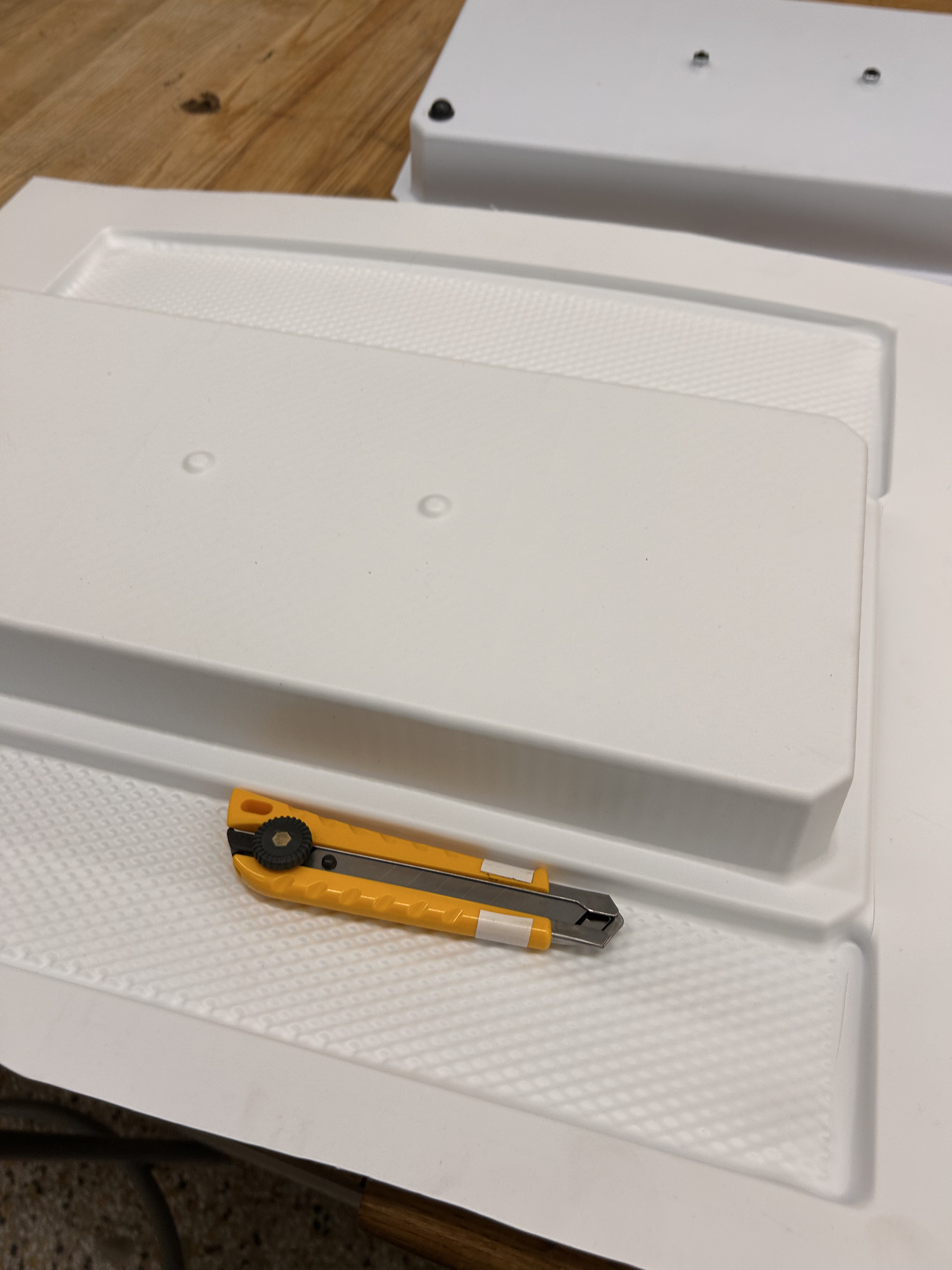

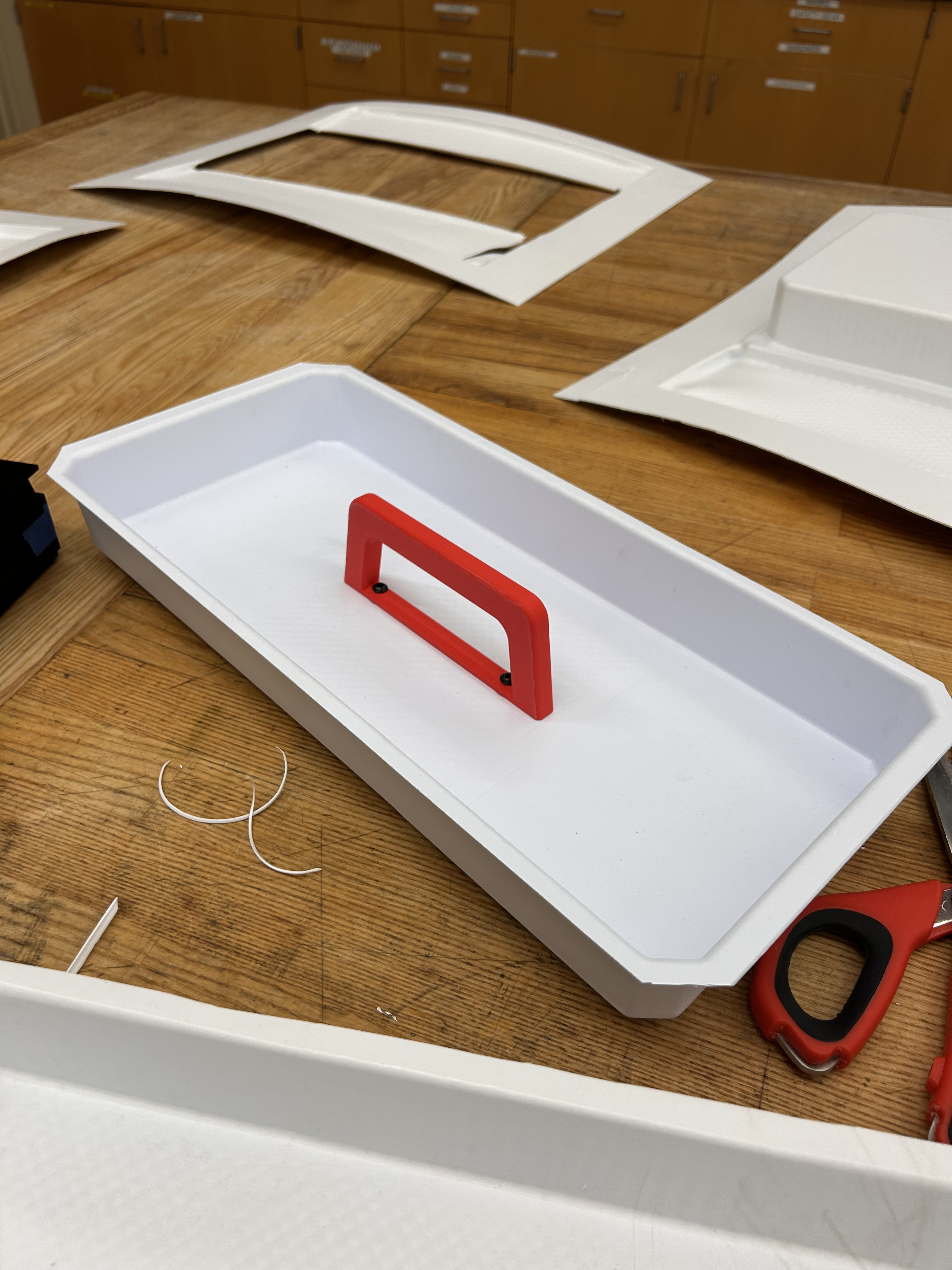

EPIC is always improving its organizational system, and recently purchased toolboxes for individual toolkits needed another shelf/bin space for storage. EPIC wanted to make bins in-house that would fit the toolboxes perfectly. The process involved cutting bulk-ordered plastic sheets to size, starting and setting up the in-house Formech Vacuum Thermoforming machine, loading 3D-printed molds into the tray, fixing plastic sheets to the machine, and turning on the heating element. After pressing and vacuum molding the plastic sheets into bin-shape, the parts were cut to final shape, edges were deburred, and 3D-printed handles were attached to complete the bins. Finally, the finished bins were tested for proper fit in the new toolboxes to ensure they met EPIC's organizational needs.

Complete documentation of the thermoforming process from setup to completion

Watch the vacuum thermoforming process in action